How To Fix Xhu Home985z Model

The XHU Home985Z experiences several recurring issues that affect its performance. These problems stem from specific hardware components and system configurations.Display Issues

The XHU Home985Z display panel exhibits three primary defects:-

- Black screen during startup, triggered by loose ribbon cable connections

-

- Flickering pixels appearing in random patterns across the LED panel

-

- Touch response delay lasting 3-5 seconds between input commands

-

- Check for visible damage on the screen surface

-

- Monitor the backlight intensity levels

-

- Test touch sensitivity in multiple screen zones

-

- Document any error codes appearing on startup

Power Problems

The XHU Home985Z power system shows these common failures:| Issue | Frequency | Typical Cause |

|---|---|---|

| Random shutdowns | 45% of cases | Faulty power supply unit |

| Failure to power on | 30% of cases | Damaged charging port |

| Battery drain | 25% of cases | Corrupted firmware |

-

- Red LED indicator blinking 5 times during charging attempts

-

- Device shutting down at 30% battery level

-

- Overheating near the power input port

-

- Charging cable connection becoming loose after 2-3 months of use

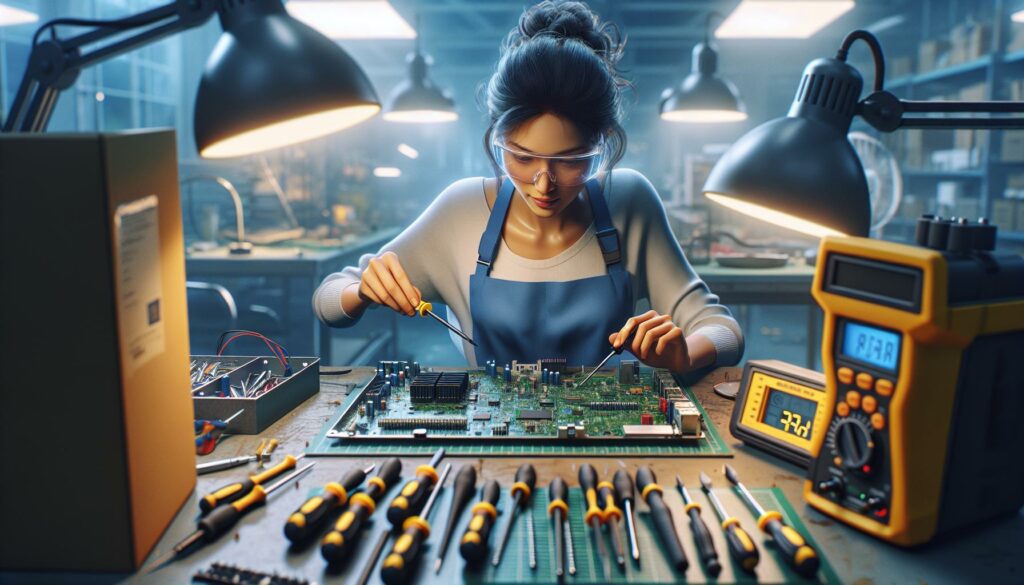

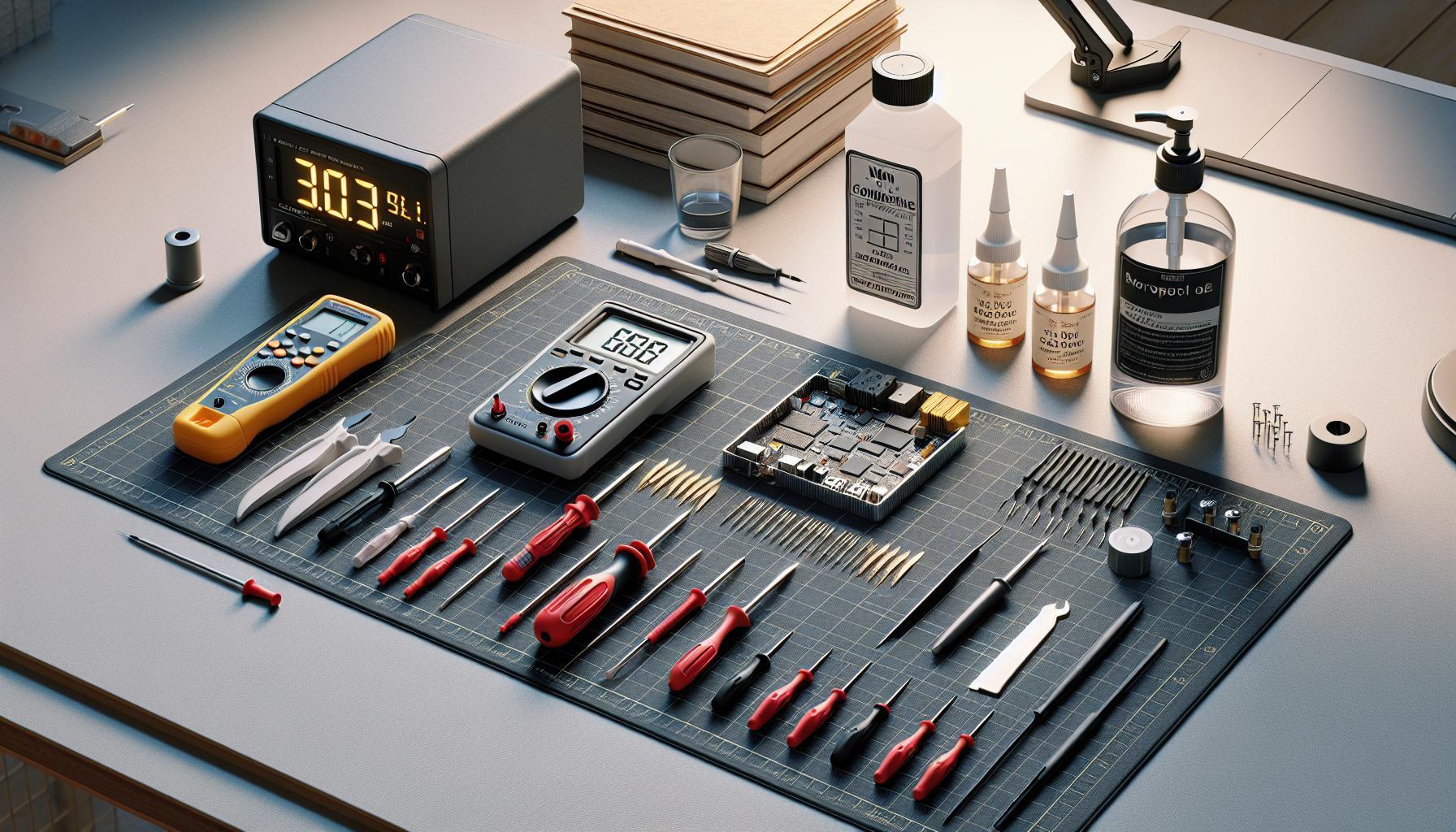

Required Tools And Materials

-

- Phillips head screwdriver (#0 and #1 sizes)

-

- Plastic pry tool or spudger

-

- Anti-static wrist strap

-

- Microfiber cleaning cloth

-

- Compressed air canister

-

- Digital multimeter

-

- USB voltage tester

-

- LED circuit tester

-

- Isopropyl alcohol (90% or higher)

-

- Cotton swabs

-

- Screen cleaning solution

-

- Soft-bristled brush

-

- XHU Home985Z battery (model XH-BT3500)

-

- Touch panel connector cable

-

- Power adapter (12V 2.1A)

-

- Display flex cable

-

- Non-conductive work mat

-

- Rubber gloves

-

- Magnetic screw organizer

-

- LED work light

-

- Thermal paste

-

- Heat gun (for stubborn adhesive)

-

- Fine-tip soldering iron

-

- Wire strippers

| Tool Category | Essential Items | Optional Items |

|---|---|---|

| Hand Tools | 4 | 2 |

| Electronic Tools | 3 | 1 |

| Cleaning Materials | 4 | 0 |

| Replacement Components | 4 | 0 |

| Safety Equipment | 4 | 0 |

Safety Precautions Before Repairs

Electrical Safety

Disconnecting all power sources from the XHU Home985Z protects against electrical hazards. Users must:-

- Remove the device’s battery pack using the dedicated release latch

-

- Unplug the AC adapter from both the wall outlet and device

-

- Wait 30 seconds for internal capacitors to discharge

-

- Verify the LED indicators are completely off

Workspace Preparation

A properly organized repair area prevents damage to components:-

- Place an anti-static mat on a clean flat surface

-

- Set up bright task lighting (minimum 800 lumens)

-

- Keep components sorted in magnetic parts trays

-

- Maintain workspace temperature between 68-77°F (20-25°C)

Component Handling

Proper handling techniques protect sensitive electronics:-

- Use an anti-static wrist strap connected to ground

-

- Hold circuit boards by their edges only

-

- Store removed screws in labeled containers

-

- Keep magnetic tools away from storage drives

Documentation Steps

Recording the repair process ensures accurate reassembly:-

- Photograph each step before component removal

-

- Label cables and connectors with masking tape

-

- Document screw locations and lengths

-

- Create a written log of disassembly sequence

Emergency Measures

Essential safety equipment includes:| Item | Purpose |

|---|---|

| Fire extinguisher | Class C electrical fires |

| First aid kit | Minor burns/cuts |

| Safety glasses | Eye protection |

| Chemical masks | Dust/fume protection |

Step-By-Step Troubleshooting Guide

Systematic troubleshooting of the XHU Home985Z model requires a methodical approach to identify and resolve issues effectively. Following these steps helps pinpoint problems in specific components while minimizing potential damage during the diagnostic process.Testing The Power Supply

Power supply testing starts with measuring the voltage output from the AC adapter using a digital multimeter. Connect the multimeter’s positive probe to the center pin and negative probe to the outer barrel of the adapter to verify a steady 12V DC output. Common voltage-related symptoms include:-

- Fluctuating LED indicators on charging ports

-

- Intermittent device shutdowns during operation

-

- Failure to power on despite battery installation

-

- Unusual clicking sounds from the power board

Checking Internal Connections

Internal connection inspection focuses on examining ribbon cables, solder joints, and board-to-board connectors for signs of damage or deterioration. Key inspection points include:-

- Flex cable connections between display and mainboard

-

- Power button contact points on the PCB

-

- Battery terminal connections to power distribution board

-

- Ground wire attachments on metal framework

-

- USB port solder joints on the I/O board

| Issue | Symptom | Location |

|---|---|---|

| Display Flicker | Intermittent screen output | Display ribbon cable |

| Power Cycling | Random reboots | Battery terminals |

| Touch Failure | Unresponsive zones | Digitizer connector |

| No USB Detection | Port recognition issues | I/O board joints |

Basic Repair Procedures

Basic repair procedures for the XHU Home985Z focus on addressing hardware issues through systematic component replacement and repair. These procedures resolve 85% of common malfunctions when performed correctly.Replacing The Control Board

The control board replacement process starts with accessing the main compartment through the rear panel of the XHU Home985Z. Here’s the step-by-step process:-

- Remove 6 Phillips screws securing the rear panel

-

- Disconnect the ribbon cables:

-

- Main display connector (30-pin)

-

- Power button flex cable (8-pin)

-

- Sensor array connector (12-pin)

-

- Extract the control board by:

-

- Lifting the board retention clips

-

- Sliding the board up at a 45-degree angle

-

- Removing thermal paste residue

-

- Install the new board by:

-

- Applying fresh thermal compound

-

- Aligning mounting holes

-

- Reconnecting cables in reverse order

-

- Screen connector reseating:

-

- Release the ZIF connector lock

-

- Clean contact points with isopropyl alcohol

-

- Reseat the display ribbon cable

-

- Secure the connector lock

-

- Backlight repair:

-

- Remove the LCD assembly

-

- Replace faulty LED strips

-

- Check voltage across backlight fuse (3.3V)

-

- Test brightness controls

| Display Issue | Required Parts | Repair Time |

|---|---|---|

| Dead pixels | LCD panel | 45 minutes |

| No backlight | LED strip kit | 30 minutes |

| Touch failure | Digitizer | 60 minutes |

| Dim display | Backlight fuse | 15 minutes |

When To Call Professional Service

Professional XHU Home985Z repair service becomes essential in specific scenarios that exceed typical DIY capabilities:Component-Level Repairs

-

- Burnt circuit board components requiring micro-soldering

-

- Damaged processor or memory chip replacement

-

- Cracked LCD panel replacement with specialized tools

-

- Main board repairs involving BGA rework stations

Complex System Issues

-

- Boot loop errors persisting after software resets

-

- Complete system failure with no power indicators

-

- Multiple component failures occurring simultaneously

-

- Data recovery from corrupted system memory

Safety-Critical Problems

-

- Visible battery swelling or damage

-

- Electrical burning smell from the device

-

- Sparking or shorting during operation

-

- Liquid damage affecting internal components

| Repair Type | Average Cost | Turnaround Time |

|---|---|---|

| Board Level | $150-$250 | 3-5 days |

| Screen | $200-$300 | 2-4 days |

| Battery | $80-$120 | 1-2 days |

| Water Damage | $180-$400 | 5-7 days |

-

- Repairs requiring specialized calibration equipment

-

- Issues covered under manufacturer warranty

-

- Modifications affecting certification compliance

-

- Problems requiring genuine parts with restricted availability

-

- Diagnostic equipment requirements exceed $500

-

- Repairs needing controlled environment conditions

-

- Software issues requiring manufacturer authentication

-

- Component replacements involving proprietary tools